CONSTRUCTION

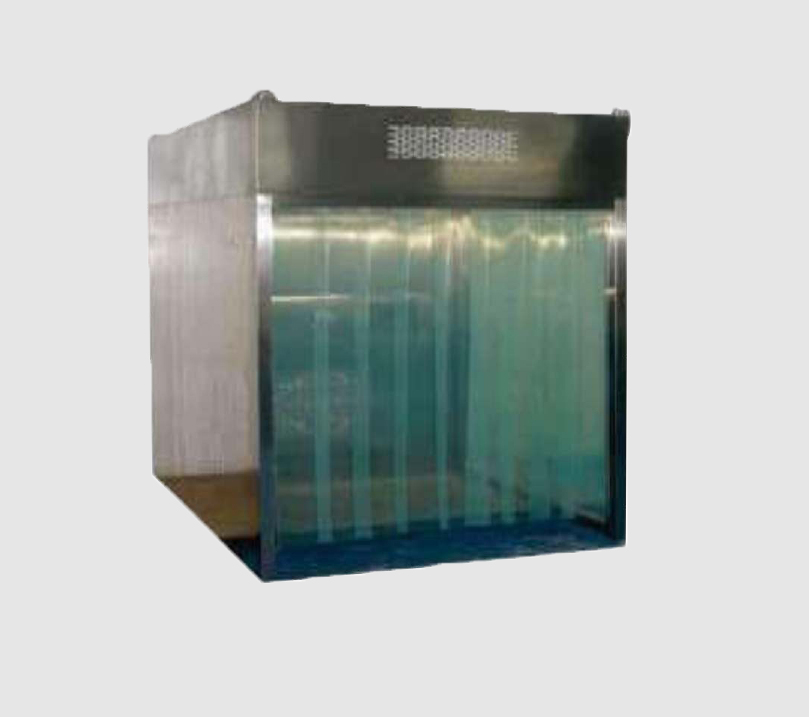

Sampling/dispensing booth is made using premium quality inner & outer SS304.Sampling/ dispensing booth unit is provided with light weighted statically and dynamically balanced motor-blower along with isolator, with an aim to reduce the noise levels. Sampling/ dispensing booth has been designed to provide a class 100 working environment at rest, with built-in scavenging system to ensure protection for the product operator and surrounding environment.

SPECIFICATION

Minimum vibration level.

Complete inner & outer SS304/Inner SS304 Two stage filtration/three stage filtration.

A unique combination of the most customizes design with the highest product protection operator comfort versatility and reliability. Delivered with a strong table top made of stainless steel.

HEPA filter with hot melt technology which conforms to EU 14 Grade with an efficiency rating better than 99.99% for 0-3μ at supply position.

HEPA filter with hot melt technology which conforms to EU 14 Grade with an efficiency rating better than 99.99% for 0-3μ at exhaust position pre filter which conforms to EU 4 Grade with efficiency of 90% down to 10 μ, These filters are basically made from micro fibre-glass media and are inherently washable.

Intermediate filter which conforms to EU7 Grade with efficiency of 95% down to 5μ. These filters are basically made from micro-fibre glass media and are inherently washable.

Motor blower provided are statically and dynamically balanced supply of sufficient capacity and static pressure is used to take

care of air low requirement for entire life of HEPA. The blower is high performance noise abated light weighted statically and dynamically balanced.